Pet Food, Flavouring & Food Odour Control

ERG is a leading supplier of Odour Control Systems for Flavourings, Food and Pet Food Manufacturing

ERG is an experienced Odour Control supplier, providing cost-effective solutions to the Flavourings, Food and Pet Food Manufacturing Industry for more than 20 years.

Cost-effective odour control systems

Our bespoke packages are designed for your site’s specific requirements to give efficient, safe and simple odour control – minimising nuisance odours for your staff and neighbours.

Whether you need an Odour Control Unit for a new facility, or an upgrade or retrofit to an existing process line, each of our systems comes with a performance guarantee to match your odour permit and uses the most effective treatment steps to keep your capital and operating costs as low as possible.

Our clients include some of the biggest international food brands and smaller local manufacturing sites. For each we offer the same professional service – including helping support your discussions with the Local Authority or Environmental Agency.

We have experience treating odorous air from diverse processes including semi-moist pet food granulators, processed food frying operations, flavourings spray dryers and vegetable oil processing.

Most odorous air streams can be treated using a combination of a chemical scrubber and carbon filter. A minority of projects can also be treated by thermal oxidation.

Typical systems include some or all of the following:

- Building and LEV (Local Exhaust Ventilation) ductwork

- Single or multi-stage chemical scrubbing for bulk-treatment of odorous, complex organic compounds using packed tower scrubbers, tray scrubbers or venturi scrubbers – including as required chemical storage and dosing packages.

- Sub-coolers to condense water vapour and certain odorous compounds

- Thermal oxidiser

- Extraction fan

- Polishing carbon filter and discharge stack

Typical odour concentrations at the stack are 1,000 ouE/m3, rising to 3,000 ouE/m3 for highly odorous operations with tall discharge stacks to aid dispersion.

Complete Odour Control Packages

ERG provides a comprehensive service:

- Design of the complete Odour Control System including:

- Interface with processing equipment – direct connections and extract hoods

- Extraction ductwork and associated supports

- Odour control system – chemical scrubber, and/or carbon filter, or thermal oxidation, and fans

- Chemical storage and dosing, and simple effluent treatment

- Extracted air cooling and reheating

- Control package – MCC/C&I panel, instrumentation, power and control cabling

- Discharge stack and monitoring

- Access structure

- Procurement and manufacture of system equipment items

- Delivery and off-loading

- Mechanical and electrical installation of the system equipment items including site supervision

- Commissioning and management of performance testing

- Complete documentation package

- Maintenance contracts

Design Services

We have extensive design capabilities. In addition to straightforward design and build Odour projects, our clients also benefit from:

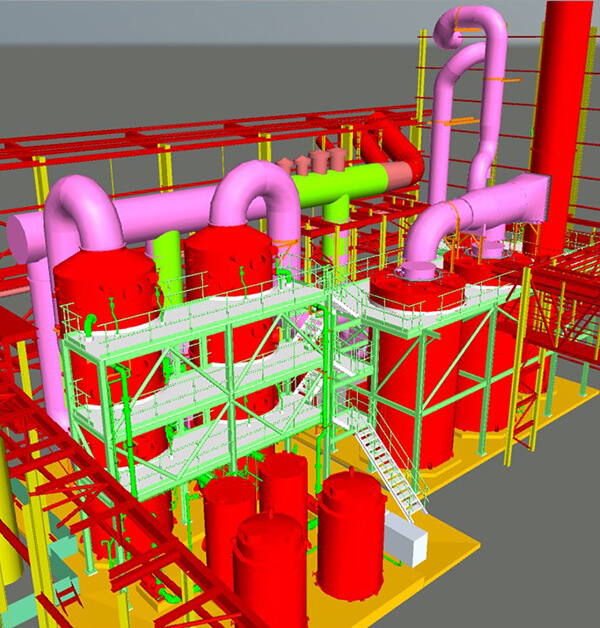

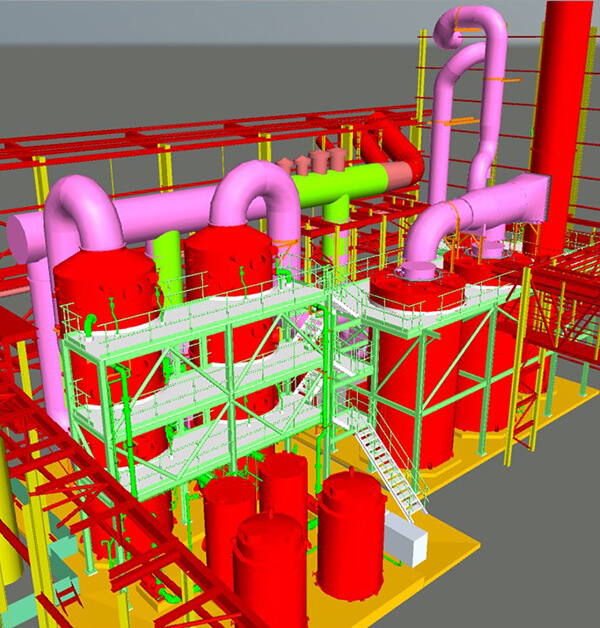

- 3D modelling of all packages – we model using Plant 3D and export as .dwg and Navisworks

- BIM integration where required

- Optioneering and FEED contracts

All design and build contracts include a complete set of design deliverables as standard. In all cases, our designs use best practice as described in the Environment Agency Guidance H4 Odour Management.

Optioneering and FEED (Front End Engineering Design) contracts

Existing food and pet food manufacturing sites are often under pressure to expand capacity and reduce their odour impact on new or established neighbours.

ERG can help with defining the available options for upgrading existing assets and the preliminary engineering to allow formal project budgets to be set or released for implementation. We provide competitively priced design work carried out by our team of graduate and chartered engineers. In each case, the design output and consultancy fee is tailored to meet the needs of the project – typical deliverables include:

- Engineering review and testing of the current system

- Summary report identifying the available options for reusing/upgrading odour control assets versus providing new OCU(s), including a BAT assessment consistent with current BREF, drawing on any available third party odour monitoring or ERG’s pilot trials

- Details of the technical and construction pros and cons of each option

- Indicative CapEx and OpEx costings for major options

- Preliminary engineering design for selected option – input to the formal project specification

Read about how this approach has benefitted several of ERG’s clients who have recently implemented large odour control projects to improve their site’s existing odour control.

Project Management and Site Services

Our project management and site staff are dedicated to ensuring each project is completed safely and to the full project requirements. All staff site managers and/or supervisors hold SMSTS or SSSTS certification, and all our staff have an applicable CSCS (or equivalent) card. Where required, we can act as the CDM Principal Contractor.

Most retrofit projects require detailed planning of interfaces and temporary works to limit disruption to production, and manual handling of large equipment in areas with limited access. ERG has significant experience of successfully managing these requirements.

Case Studies

You can download and read our case studies and brochures of the range and products.

Customers

ERG’s clients include major international brands and smaller local manufacturers.

Pet Food, Flavouring & Food Odour Control

ERG is a leading supplier of Odour Control Systems for Flavourings, Food and Pet Food Manufacturing

ERG is an experienced Odour Control supplier, providing cost-effective solutions to the Flavourings, Food and Pet Food Manufacturing Industry for more than 20 years.

Cost-effective odour control systems

Our bespoke packages are designed for your site’s specific requirements to give efficient, safe and simple odour control – minimising nuisance odours for your staff and neighbours.

Whether you need an Odour Control Unit for a new facility, or an upgrade or retrofit to an existing process line, each of our systems comes with a performance guarantee to match your odour permit and uses the most effective treatment steps to keep your capital and operating costs as low as possible.

Our clients include some of the biggest international food brands and smaller local manufacturing sites. For each we offer the same professional service – including helping support your discussions with the Local Authority or Environmental Agency.

We have experience treating odorous air from diverse processes including semi-moist pet food granulators, processed food frying operations, flavourings spray dryers and vegetable oil processing.

Most odorous air streams can be treated using a combination of a chemical scrubber and carbon filter. A minority of projects can also be treated by thermal oxidation.

Typical systems include some or all of the following:

- Building and LEV (Local Exhaust Ventilation) ductwork

- Single or multi-stage chemical scrubbing for bulk-treatment of odorous, complex organic compounds using packed tower scrubbers, tray scrubbers or venturi scrubbers – including as required chemical storage and dosing packages.

- Sub-coolers to condense water vapour and certain odorous compounds

- Thermal oxidiser

- Extraction fan

- Polishing carbon filter and discharge stack

Typical odour concentrations at the stack are 1,000 ouE/m3, rising to 3,000 ouE/m3 for highly odorous operations with tall discharge stacks to aid dispersion.

Complete Odour Control Packages

ERG provides a comprehensive service:

- Design of the complete Odour Control System including:

- Interface with processing equipment – direct connections and extract hoods

- Extraction ductwork and associated supports

- Odour control system – chemical scrubber, and/or carbon filter, or thermal oxidation, and fans

- Chemical storage and dosing, and simple effluent treatment

- Extracted air cooling and reheating

- Control package – MCC/C&I panel, instrumentation, power and control cabling

- Discharge stack and monitoring

- Access structure

- Procurement and manufacture of system equipment items

- Delivery and off-loading

- Mechanical and electrical installation of the system equipment items including site supervision

- Commissioning and management of performance testing

- Complete documentation package

- Maintenance contracts

Design Services

We have extensive design capabilities. In addition to straightforward design and build Odour projects, our clients also benefit from:

- 3D modelling of all packages – we model using Plant 3D and export as .dwg and Navisworks

- BIM integration where required

- Optioneering and FEED contracts

All design and build contracts include a complete set of design deliverables as standard. In all cases, our designs use best practice as described in the Environment Agency Guidance H4 Odour Management.

Optioneering and FEED (Front End Engineering Design) contracts

Existing food and pet food manufacturing sites are often under pressure to expand capacity and reduce their odour impact on new or established neighbours.

ERG can help with defining the available options for upgrading existing assets and the preliminary engineering to allow formal project budgets to be set or released for implementation. We provide competitively priced design work carried out by our team of graduate and chartered engineers. In each case, the design output and consultancy fee is tailored to meet the needs of the project – typical deliverables include:

- Engineering review and testing of the current system

- Summary report identifying the available options for reusing/upgrading odour control assets versus providing new OCU(s), including a BAT assessment consistent with current BREF, drawing on any available third party odour monitoring or ERG’s pilot trials

- Details of the technical and construction pros and cons of each option

- Indicative CapEx and OpEx costings for major options

- Preliminary engineering design for selected option – input to the formal project specification

Read about how this approach has benefitted several of ERG’s clients who have recently implemented large odour control projects to improve their site’s existing odour control.

Project Management and Site Services

Our project management and site staff are dedicated to ensuring each project is completed safely and to the full project requirements. All staff site managers and/or supervisors hold SMSTS or SSSTS certification, and all our staff have an applicable CSCS (or equivalent) card. Where required, we can act as the CDM Principal Contractor.

Most retrofit projects require detailed planning of interfaces and temporary works to limit disruption to production, and manual handling of large equipment in areas with limited access. ERG has significant experience of successfully managing these requirements.

Case Studies

You can download and read our case studies and brochures of the range and products.

Customers

ERG’s clients include major international brands and smaller local manufacturers.